A Q&A with Indmar’s product team

In 2015, Indmar, in partnership with Ford, introduced the ROUSH-charged Raptor engine to the inboard market, winning several industry awards, including being one of Boating Industry’s Top Products of the Year. In 2016, Indmar is expanding the Raptor line to new market segments. We talked to some of the Indmar product development team – vice president Scott Clack, vice president of engineering Jason Stimmel and design engineer Rachel Masburn – about the new engines, and its new accessory, the Strainer Pro, which won an innovation award at this year’s Miami International Boat Show.

Boating Industry: So last year, you introduced the Raptor engine, and now you’re expanding it to the cruiser and jet segment. What’s driving that decision?

Clack: The short answer was that if we’re getting into other markets, cruisers seemed to be a perfect fit. If you look at the 6.2 and the performance of it … it’s diesel performance in a gasoline engine. We thought this would be really nice, even as far as a retrofit if you’re looking for repower, not just an OEM product.

The ski boat/wake boat segment is pretty compressed when you start looking at the players in it. …

All of our OEMs … are all on board with the engine now and it’s proven to be a really strong performer. So we look at that segment and arguably it’s pretty saturated right now, so what else makes sense?

You look at the jet boat market … and they were asking for it.

We took a pretty aggressive stance in going up into the Northwest and getting a foothold there, setting up shop up there and we have a service station and tech and warehouse up there.

Boating Industry: What are you learning in those markets?

Clack: [Jet boats] are a different market for us … they’re a lot more technical. These guys are people that like to work on the product, they want to know about it. They understand the engine, but they also want to know that you’re going to be there for them.

Now, moving into 2016, there’s a lot of positive feedback, we’re starting to get a lot more calls, a lot more interest.

Cruiser is something we’re going to continue to work at. We understand the market is pretty flat right now, but we look at what does this engine bring to that segment? We think this is a great opportunity to bring new technology to that market.

Boating Industry: What do you think are the advantages you’re offering in that market?

Clack: One is gasoline prices are dropping and you’ve got performance in the 6.2 product. You’ve got better fuel economy now, you’ve got a quieter engine, you’ve got performance that brings those torque values in. It’s a great package and price is a huge differentiator, as compared to a diesel-powered product.

We’re going to dip our toe in the water. Our passion is boating and all aspects of it. Our heritage has been in the water ski and wake business, but we’re all boaters. We just want to be out on the water and we think there’s opportunity with these products.

The wake and water ski segment tends to drive innovation, it’s more accepted. We’ve proven ourselves to the industry, it’s a brand that’s well known, it’s a brand that speaks quality and service and we think that can translate over to the cruiser market.

Boating Industry: Now that the Raptor has been in the market for a year, what’s been the reaction from your OEMs and consumers?

Clack: Well, I can tell you the phones are quiet from a warranty standpoint. Dealers absolutely love the product. Our warranty problems are double-digit down with this product.

Working with Ford, engineering put a lot of time and effort into building this product, putting in the safety features and all of the mechanisms that we learned over the years. That is one of the main things we’re hearing: we don’t see the overheating of the engines, we don’t see performance issues, we just don’t hear about it. It’s all planned and the plan is working.

Working with Ford, engineering put a lot of time and effort into building this product, putting in the safety features and all of the mechanisms that we learned over the years. That is one of the main things we’re hearing: we don’t see the overheating of the engines, we don’t see performance issues, we just don’t hear about it. It’s all planned and the plan is working.

We offer a single platform with three different options, so from an OEM standpoint, installs, parts … everything is pretty common across the board.

We offer a single platform with three different options, so from an OEM standpoint, installs, parts … everything is pretty common across the board.

We’re trying to commonize everything. From a production standpoint, it has really streamlined production. …

The ROUSH brand is a strong brand. We align ourselves very well with those two companies. They have a rich history of performance and quality. Those guys were on board from day one, helping develop the entire package. It’s been fun, it’s been challenging for all of us, because we are by far outpacing what our [sales] projections were.

Boating Industry: What are some of those features that have made it successful?

Stimmel: I think one of the big assets with Ford is we offer freshwater cooling as a standard option. The advantages to the consumer are huge: you won’t get any corrosion through the block, the pumps on the block will last longer. It’s one of the reasons we could go with a five-year factory warranty. The conventional automotive alloys will not stand up to saltwater, so [freshwater cooling] is good for the OEM and it’s good for us.

We tried to optimize the drainage system so all the points on the engine you do have to touch, they’re all well indicated, easy to take apart. You have to drain five points, and it’s pretty much winterized.

Clack: I will tell you, there’s a lot of pressure in the market, as these boats get larger and continue to creep up in pricing. … The easiest way we bring cost out of the engine is to take closed cooling off of it. We firmly believe that closed cooling is a tremendous benefit, and we’re the only ones out there that offer it standard. It’s the right thing to do for the consumer, it’s the right thing to do for the performance of the engine.

What we’re seeing out there in the market, you look at the results of some of these aluminum blocks that aren’t running closed cooling, the life expectancy is not very good. The consumer is going to feel the brunt of that.

If you want to grow the business, if you want to grow boating, consumers have to have a good experience. We need them to continue to want to be boaters and to bring other people out there.

Stimmel: We’ve gone to cartridge canisters. We’re being good environmental citizens in this regard. We’re not sending the old canister styles to the landfill. If you send the cartridge to a proper recycling center, they just incinerate the paper element, instead of crushing the can and leaking the oil out of it.

Especially now that all of our engines are catalyzed, we are engaging a more environmentally conscious consumer as well.

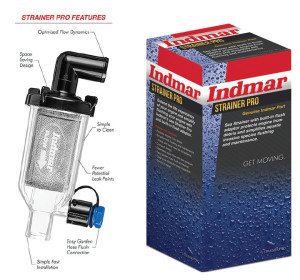

Boating Industry: Let’s talk about the Strainer Pro. How did that come about?

Clack: This goes back to one of the key challenges we have. We think we build a very good, quality, purpose-built product. We provide the product to the OEM, we work with them on the install, but we don’t have a lot of control over the engine after it leaves our factory.

We require certain water flow and air flow and all the things you need in that package, but honestly we’re not sitting there auditing every single engine. Water flow is a key component. You put a part between the water pickup and the engine itself in the sea strainer that is arguably suspect … that’s a key area. All of the sudden, you’ve got engine issues.

I can tell you, it’s cost us tens of thousands of dollars over the years trying to chase down what a problem might be. So these guys said, “Look, we can make one of these things. Why don’t we design our own?”

This group put it together and the design came from Rachel. She wasn’t an engine geek, didn’t know about engines. She didn’t know any better, which is really kind of neat. She didn’t know that it can’t be done, or you shouldn’t do that, so she had a whole different approach.

Masburn: It was incredible that we were able to do that, that the company gave me that opportunity because at the time I was pretty green. They let me go with it and now we’ve got the innovation award to take back. … They said, this is what we needed to do, and we figured it out. It’s a great team, helping each other out all the time and that’s why we’re able to [create] these products. … Jason just does a great job of letting us go, and I can say “Let’s just try this and see what happens.” Sometimes I realize something is a terrible idea, but sometimes it works.

CLACK: We went into an area that was kind of unique for us, bringing parts and accessories to the market, but I think that’s a direction you’ll start seeing more of from Indmar, looking outside the engine and at the system as a whole.

There’s a new energy at our company. We spent years and a lot of resources both financially and with our employees to bring Ford back to the market and we took a huge chance. We bet the company on it and it’s proven to be the right thing to do.