Apprenticeship: One approach to tech shortage

Institutions, industry address critical workforce issue

The workforce shortage in the marine industry remains in a state of crisis, but companies are taking active steps toward finding and retaining the technicians and skilled laborers of the future.

The majority—over 80 percent by some estimation—of marine technicians still gain their core skills through on-the-job training, according to the Marine Career Training Institute of North America, based in Canton, Ga.

Many companies today have access to manufacturer training, which is fine as far as it goes, but it’s limited to product-specific information from each particular manufacturer, and it relies on the technician already possessing proper core skills.

Twenty-first century apprenticeships are evolving as a potential solution to equip highly trained workers with the skills needed to contribute to a dealership’s success and to the economy as a whole.

Companies that use apprenticeship report higher productivity, higher retention rates, and a substantial return on investment.

But employers, community colleges, workforce practitioners, and apprenticeship coordinators are still struggling to understand how to expand the adoption of apprenticeship to more companies, occupations, and workers, said Scott Ellsworth, a contract consultant who is working with Jobs for the Future, a national non-profit that designs, scales, and influences systems change in the U.S. education and workforce fields.

Skills Gap Closure

Ellsworth spoke at the 2018 International Marina and Boatyard Conference in February. His presentation, “Closing the Skills Gap,” explained while competition is fierce, the burden remains on employers to attract and retain the best and brightest. Ellsworth offered recommendations for where to start and how to train and retain the best workers.

“The boating industry is behind,” Ellsworth said. “Employers understand they have to step up and do something, but other industries [recreational vehicle and automotive, for example] are working hard on apprenticeships, and bringing more people in and training them.”

According to Ellsworth, the struggle involves an industry that primarily has smaller employers who are deep into the day-to-day of improving their businesses. “When it comes to longer-term, workforce can be much, much harder for them to support,” he said. “Apprenticeships involve a very structured approach to transferring knowledge. You provide assurance that everything you wanted to teach, you’ve taught.”

The boating industry has two significant technical training obstacles to overcome, said Todd Larson, marine repair instructor at Wisconsin Indianhead Technical College in Ashland.

No. 1 is having a supply of entry-level technicians entering the workforce. Entry level technicians have to be increasingly technically savvy and have a good base of troubleshooting skills, he said.

This is where WITC’s Marine Repair Technician Program, and other training programs can help.

“The industry just doesn’t have the time to teach a budding technician the basics of engines on the job anymore,” Larson said. “Technicians need to enter the workforce with better knowledge of engine and boat systems. We have been promoting the idea where the dealer seeks out and hires an entry-level technician, sends that technician to our training program, and then employs them upon graduation.”

This is a win for the business, as they can seek out applicants from the local area, often from high school tech-ed programs. The applicants will likely want to stay and work in that specific area, Larson explained.

“I get calls every day from marine businesses looking for technicians, but there just aren’t enough to go around. Colleges just don’t have the marketing budgets to attract enough students to fill every seat in the classroom. We need help from the marine businesses. They need to go out into the community and promote the trade,” he said.

Larson suggested a “bottom-up” solution, putting the responsibility of finding and creating employees on the business who need them, with every single dealer taking on some of this responsibility.

“Consider it part of giving back to the community,” he said. “If every single marine business went out to one high school and made a presentation to students promoting the marine industry, I think it would make a big difference.”

A great number of technicians in the field don’t have the base knowledge of engine and boat mechanics to further their career in working on the more advanced and technically complex engines offered today, Larson contends.

Many are “stuck” in the technology that they grew up with, and have no career path or training available unless they have the ability to attend factory training.

“I believe the engine manufactures have to accept the thought that many of their engines are worked on by independent service centers, and there needs to be an industry avenue for those technicians to receive training.”

The bottom line? There are many experienced but unqualified technicians working on products, and they aren’t consistently repaired correctly.

The marine industry has to address this problem, probably in a similar way as the auto industry did many years ago. This will improve the image of the trade, improve the image of the manufactures, and attract more people to boating, Larson said.

Another problem is that it is very expensive to promote programs beyond a very local level.

“I don’t think there are many colleges with those kinds of promotional budgets,” Larson said, adding WITC’s main career promotion relies on an Internet presence, and working with state and national boating organizations.

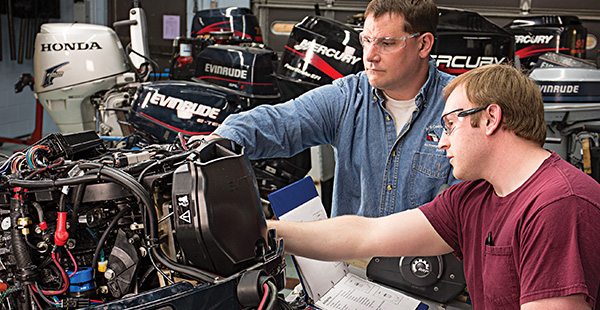

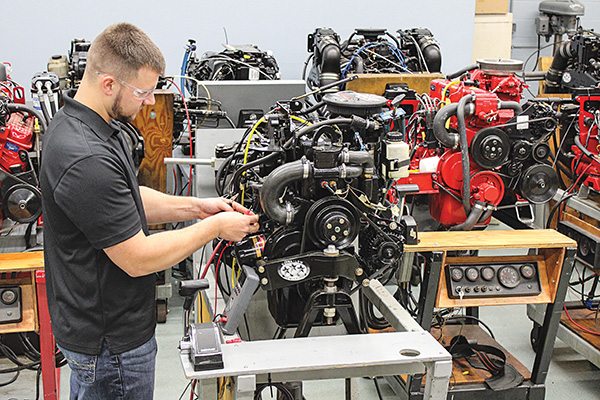

WITC’s program includes instruction on marine engine service, operation, diagnosis, repair, equipment installation, maintenance and rigging new boats. Students work on modern engines from manufactures such as Mercury Marine, Evinrude, Yamaha, Honda, and Volvo Penta.

“I think all colleges have figured out that we are all competing for a dwindling supply of prospective students. All of the trades are attempting to lure the same type of student, being it plumbing, construction, or marine technicians.”

Apprenticeship is one way to connect prospective workers and marine businesses, Larson said.

“Apprenticeships can work very well for the right business, especially if there is funding to offset the costs,” Larson said, adding a nationwide educational effort will take a lot of industry funding.

East Coast improvement efforts

Last December, the American Boat & Yacht Council announced the release of a marine service technology program to help secondary schools implement standards-based curriculum with an inland or coastal focus.

The curriculum package includes a textbook, instructor guides, PowerPoint presentations, sample test questions and online videos.

“We are thrilled to launch the only standards-based curriculum program in the marine industry and meet the needs of high school teachers,” said Ed Sherman, ABYC vice president of education. “Furthermore, by partnering with the National Occupational Competency Testing Institute (NOCTI), we can offer a nationally recognized series of exams that will provide successful students with an industry recognized entry-level credential.”

ABYC’s goal is to make it very easy to implement an engaging marine service training program that will drive interest and help young people pursue rewarding careers in the marine industry, Sherman explained.

“Before I started using ABYC’s textbook, I had to purchase several marine books to get all the material necessary for my students,” said Rob Berenwick, instructor at Ocean County Vocational Technical School.

ABYC’s effort addressed the school’s needs in one book and the new curriculum package will make easier for Ocean County’s marine program to excel, he said.

In early February, ABYC hosted eight marine industry employers, two representatives from Anne Arundel Community College, and the workforce development team from the Marine Trades Association of Maryland to discuss the creation of a marine industry apprenticeship program in the state of Maryland.

The Marine Trades Industry Partnership is funded by Maryland’s EARN Maryland Grant Program, administered by the Maryland Department of Labor, Licensing and Regulation.

The goal of the meeting, as stated by MTAM Executive Director Susan Zellers, was for a group of Marine Trades Industry Partnership Employers to evaluate and give feedback about the curriculum developed by ABYC.

With the buy-in from employers, the curriculum can be used to fulfill the classroom time required of a Maryland Marine apprenticeship program.

“ABYC’s marine service technology program was created to address the industry’s need for post-secondary technical education for aspiring marine professionals,” Sherman said. “This comprehensive curriculum gives students a jump start in their career path and is designed to be easily integrated with apprenticeship programs.”

The course ends in a final exam, which was taken by some of the employers at the table who had not completed the course.

Elliot Anderson of Hinckley Yacht Service was one of those employers. “The marine industry has many disciplines and I thought the test gave a good overview of the different elements,” Anderson said. “There were a lot of technical things and a lot of electrical content. It was thorough, longer than I expected. I would love to employ someone with the skills taught in this course.”

According to ABYC, there was general excitement regarding offering a such a course at local high schools and community colleges.

The employers present were eager to hire, but were experiencing difficulty finding workers with knowledge of the recreational boating industry.

“I can train the technical aspects of the job. I really look for someone who has a general knowledge of boats. Even if someone is an electronics whiz, some sort of baseline of basic boat knowledge would be super helpful,” said Ryan McQueeny of Marine Technical Services.

With the support of industry and education partners, MTAM will move forward with plans to work with the state of Maryland to develop an approved apprenticeship program with some of the employers in the Partnership.

“It is our hope such a program will fortify the recreational boating workforce, giving all of us a deeper pool of candidates to hire from, and strengthening the boating industry in Maryland,” said John Norton, MTAM president and owner of Annapolis Harbor Boatyard.

Florida symposium date set

In Florida, Warner University’s Institute of Marine Technology has announced plans for a June on-campus national Marine Industry Training Conference.

Designed to bring together a broad mix of industry representatives ranging from OEMs to aftermarket manufacturers, marine retailers, marina operators, industry associations and other parties, the symposium will focus on the future of the marine industry and career development requirements.

As the lack of quality trained marine personnel becomes more prevalent, organizers thought it would be important to initiate an open discussion that would cross multiple industry platforms, with the goal to addressing both short- and long-term employment needs as well as fostering a planning collaboration, said Justin Maley, event organizer and IMT administrator.

Maley has spoken directly to multiple industry businesses and reports the enthusiasm for a training dialog is encouraging.

“The idea for the conference came about simply by learning about the marine industry,” Maley said.

Prior to becoming a marine technical educator, he worked with Austrian motorcycle and sports car manufacturer KTM AG overseas and in the U.S. “I came in with my eyes wide open, and was forced to learn from scratch, and start addressing problems that were being brushed aside,” Maley said, adding he became concerned when he didn’t see a larger effort to improve technicians coming out of school.

“I don’t want to sound negative, but the marine industry is far behind other industries,” he said. “One of the benefits of us starting a brand-new program is writing a real-time curriculum.”

A lot of very, very old curriculum is still being taught, Maley added. “I went into one of the schools as part of a prior job I had with an OEM and looked at the curriculum. It had been written in 1998.”

Regarding the June conference, Maley said he’s getting a lot of interest from outboard and engine manufacturers.

“We are hoping this conference will serve a 2-for-1 purpose. We want to help the industry, and learn how we can change it,” he said.